Plank - Technical specifications

Technical specifications

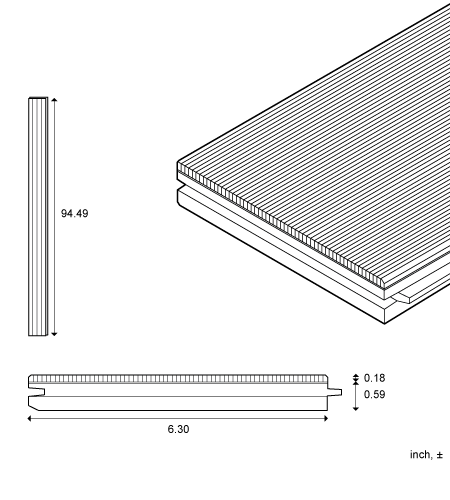

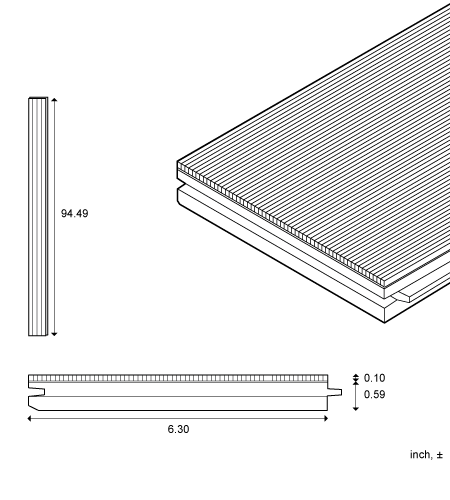

Structure: Veneer composed of strips of approximately 0.04 to 0.12" veneer of end grain wood and wood with the grain, glued crosswise, of approximately 0.18" thickness (floor), glued onto one side of a substrate, with tongue and groove, top layer has bevelled edge or 0.10" thickness (wall and ceiling), glued onto one side of a substrate, with tongue and groove

Length: Maximum length 97.64", tolerance profiled 0.2 - 0.3 %

Width: Maximum width 7.68", tolerance profiled 0.2 - 0.3 %

Thickness: Maximum thickness 0.94", tolerance sanded ± 0.01"

Squareness: ± 0.04" per 39.37"

Density: Depending on the kind of wood 400 - 800 kg/m³

Dimensional stability: According to NEN-EN 318 measured by the SHR RC 2115 at climate variations

Standard climate 20 ± 2 ºC and 65 ± 5 % RH

Dry 20 ± 2 ºC and 35 ± 5 % RH

Humid 20 ± 2 ºC and 85 ± 5 % RH

Result: Dependent on kind of wood

Lengthwise (direction of the lines) ≤ 0.1 %

Crosswise (width direction, direction square to the lines) ≤ 2 %

Thicknesswise (in the thickness direction) no measurable result

Hardness: Janka hardness scale rating according to ISO 3350, 1975 08 01, measured by the SHR RC 2115

Plexwood - Beech 5866 N

Plexwood - Birch 4822 N

Plexwood - Deal 3474 N

Plexwood - Meranti 4991 N

Plexwood - Oak 7801 N

Plexwood - Ocoumé 3606 N

Plexwood - Pine 3806 N

Plexwood - Pine/Ocoumé 3224 N

Plexwood - Poplar 2783 N

Wear resistance with oil/wax finish: Wear resistance according to NEN-EN 438-2, ISO 4586-2, 1988, measured by the SHR RC 2115-2

Test samples are treated with oil/wax Berger Seidle High Solid, and measured using the Taber® Abrasion Tester, thickness reduction which occurs after 2000 Cycles (not in conformance with norm) is, dependent on the kind of wood, 0.23 - 0.48 mm

Wear resistance with varnish finish: Wear resistance according to NEN-EN 438-2, ISO 4586-2, 1988, measured by the SHR RC 2115-2

Test samples are treated with varnish Berger Seidle Aqua-Seal 2K-PU matt, and measured using the Taber® Abrasion Tester to Final Wear Point, result is, dependent on kind of wood, 225 - 550 Cycles

Tensile strength: Measured perpendicularly according to NEN-EN 319 by the SHR RC 2115

gluing Plexwood ≥ 1.01 N/mm², the glue used by Plexwood meets quality D4 according to NEN-EN 204

Wood properties: Wood is not static, has a high electrical resistance (1 - 1000 MΩ), and a small heat conductivity (0.11 - 0.16 W/m²K) of which the effect is that it slows down the spreading of fire (source: Wood Vademecum; Wood Centre Foundation [Hout Vademecum; Stichting Centrum Hout], Almere 2001, pages 46, 48)

Size conversion: Plexwood uses the metric system in all formal communication. No rights can be derived from size conversions to the imperial system. Plexwood converts sizes for your convenience only