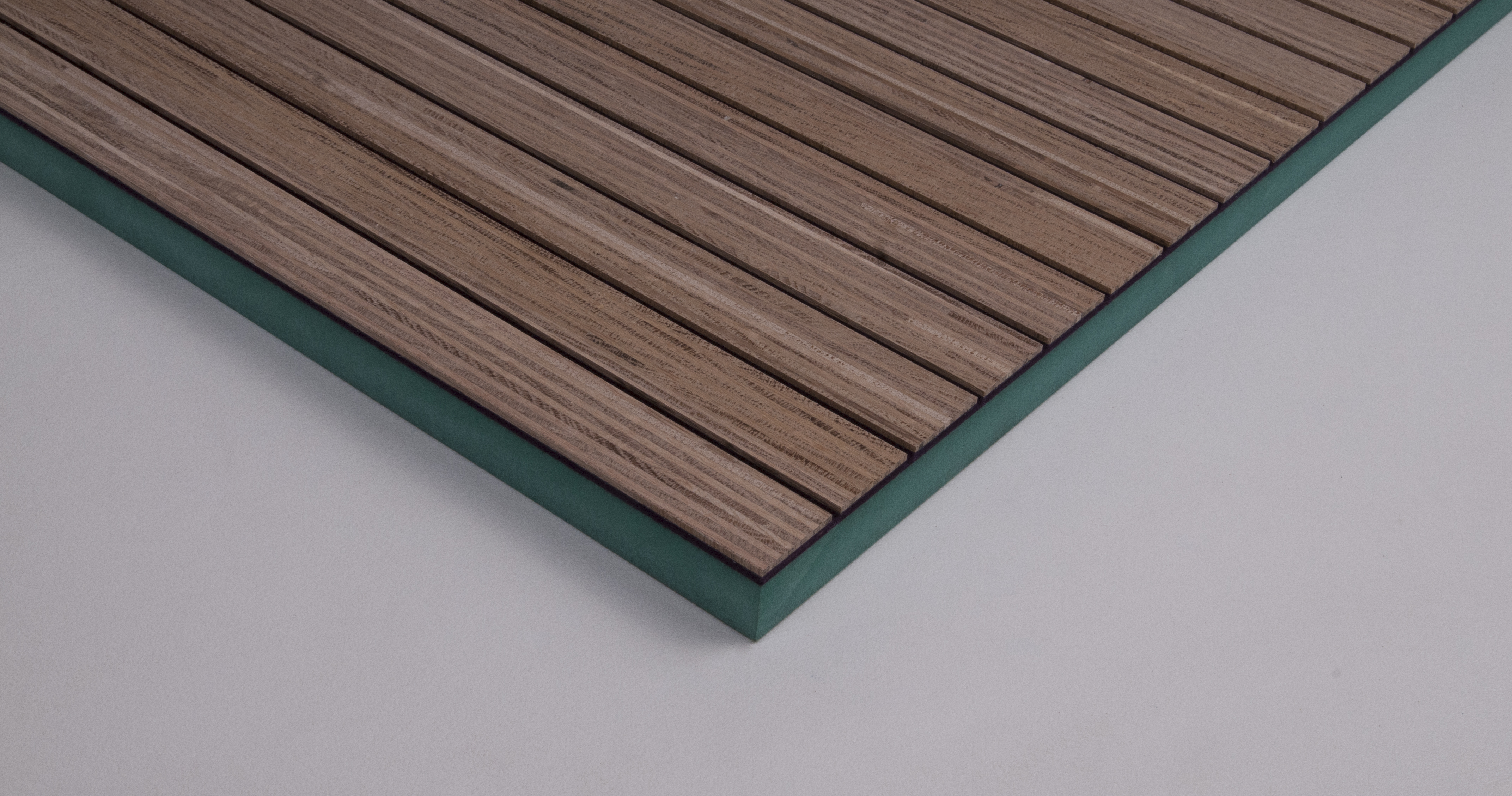

Acoustic - Processing and finishing - Acoustic - Wool felt rigid

Processing and finishing

General processing: For professional processing only, Plexwood is composed of end grain wood and wood with the grain, this means that sanding, filling, cutting, gluing and finishing differs significantly from other wood products, follow the instructions of the products chosen, and the general guidelines below

Acclimatization: Allow Plexwood to acclimatize under the conditions in which it will be used

Sanding: This product is as standard delivered finished, but are also available unfinished upon request. In that case, always sand concentrically/rotatingly, because the veneer layers differ in hardness, belt sanding is generally not suitable for this product

Filling: This product is as standard delivered finished, but are also available unfinished upon request. In that case, always work with wood fillers that are suitable for end grain wood, generally, fast-drying wood fillers are not appropriate, and run a test if necessary

Fixation: Dependent on the application, t-brads or mini-brads with small heads are usually suitable to fixate the panel with glue to the substrate or batten framework. Use a suitable non-water based construction glue, or a PU glue, generally, white water-based wood glues are not appropriate, run a test if necessary

Battenwork: When needed, install wooden battens in an appropriate manner, with a distance between each batten of at most 400 x 400 or 400 x 600 mm. Apply construction glue to batten framework, place Plexwood product into glue, and secure using for instance t-brads or mini-brads with small heads. Always ensure that seams (where 2 parts connect) are joined securely on a shared batten, on all sides

Additional installation options: When used in combination with battenwork, the desired acoustic resonance Wool felt in the space can be further improved through the use of (stone wool) insulation material (or similar product) placed in between battens, depending on your technical requirements

Connection: A butt joint (especially suitable when on matching plywood panel), connection with dowels or biscuit joints (lamellos), mitered corner joint and corner joint with corner anchors are the most common connections

Finishing: This product is as standard delivered finished with a matt, water-based varnish, further finishing of this product is not necessary. An optional fire-retardant varnish is also available. Wool felt sheets are also available unfinished on request. In that case, always choose an application method that does not stain or damage the wool felt layer, the general advice is to use a paint roller

Finishing: When finishing the product with an oil/wax yourself, please note that Plexwood is composed with end grain wood veneer, which has a higher absorption quality than wood with the grain, therefore work with oil and wax that is suitable for this type of wood structure. Generally, very thin or diluted agents are not appropriate. The manufacturer of the product in question can inform you whether their product is suitable, run a test if necessary

Finishing: When finishing the product with a varnish yourself, please note that Plexwood is composed with end grain wood veneer, which has a higher absorption quality than wood with the grain, always choose an appropriate finish, as not all acrylics and water-based varnishes are suitable for Plexwood. Generally, very thin or diluted agents are not appropriate. The manufacturer of the product in question can inform you whether their product is suitable, and if necessary, run a test